How To Take Responsibility?

Excerpts from SafetyNiti 2022

Can auto companies prevent thousands of workers from losing their fingers and hands?

Odd question, right? But have you ever wondered how many hands it took to manufacture your car? Not many of us think about this while driving to work or while stuck in a traffic jam, but the sad reality is that many of the hands that built our cars are missing fingers. Or entire limbs.

The Indian automobile industry uses manufacturing processes that put worker health at risk by making them operate machines which can hack off fingers or entire limbs if not handled with care. Unfortunately, the volumes and tight schedules mean that workers regularly end up losing digits.

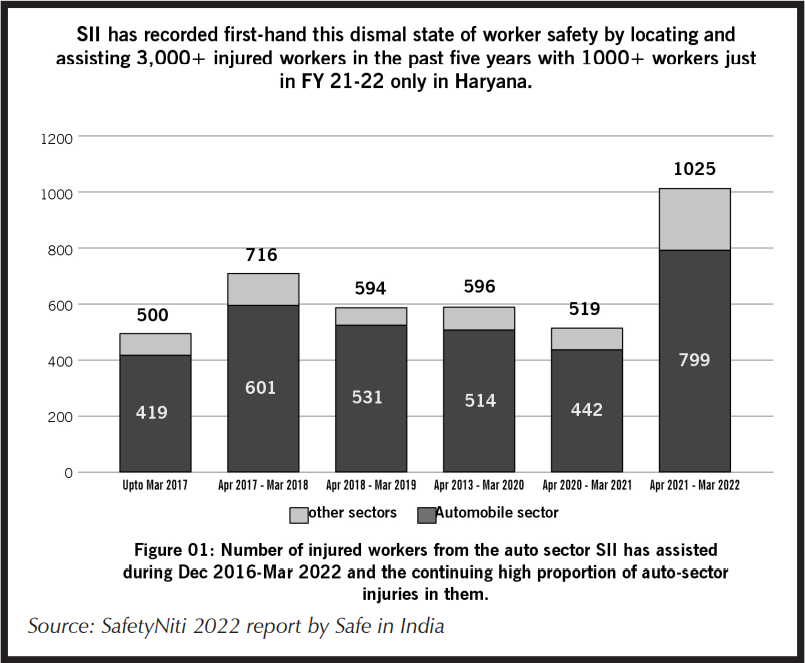

This is where Safe in India (SII) has made an invaluable intervention. When it comes to gauging the occupational safety and health (OSH) conditions at Indian automobile companies, SII has been mapping worker health in the major auto hubs across the country. Consider the following:

- In the last 5+ years, SII has located and assisted 3,955 injured auto sector workers in the auto hubs of Haryana (Gurugram, Manesar, Bawal, and Faridabad). In FY21-22 alone it provided assistance to 800 workers.

- On an average, 1.97 fingers are lost to “crush injuries”. These are injuries that result from force or pressure applied to a body part, typically heavy machinery in factories. Crush injuries have a devastating financial and psychological impact on workers and their families and restrict their already limited livelihood options

- Most auto-sector workers in the supply chains of the auto companies are migrants (80%) and contractual workers (60%).

- Nearly two-thirds of the assisted workers didn’t have ESI cards when the injuries occurred, despite paying the insurance premiums. The Employees’ State Insurance scheme (ESI) is a mandatory government social security programme for workers that protects against sickness, death and injury and applies to factories and establishments with 10 or more employees.

- Such a high toll of injuries and disablements has an enormous economic impact on the nation’s stock of skilled labour and productivity. India has dropped further from 115 in 2021 to 128 to 2022 in terms of labour productivity.

These are some of the eye-popping findings in SafetyNiti 2022, an annual report by SII which examines the OSH policies of the top 10 automobile manufacturers in India (Ashok Leyland Ltd, Bajaj Auto Ltd, Eicher Motors Ltd, Hero Motocorp Ltd, Honda Motorcycles and Scooters India Pvt Ltd, Hyundai Motor Company India, Mahindra and Mahindra Ltd, Maruti Suzuki Ltd, Tata Motors Ltd, and TVS Motor Company Ltd).

This year’s report is the second after the inaugural one in 2021. It looks at publicly available OSH documents that Original Equipment manufacturer (OEMs, which are the actual automobile companies) have for their own factories and those of their supply chains. SII went through these documents to ascertain what processes were in place to prevent accidents, learn from past accidents, and improve worker safety.

As an illustration of the impact that the report is having, SafetyNiti 2022 has found improvements in the OSH policies of many of the top 10 OEMs in line with recommendations made in SafetyNiti 2021.

Following are some of the findings of SafetyNiti 2022.

FINDING 1

OSH Policy in Public Domain

Although all 10 OEMs mention they have an OSH policy for their own factories, six have it in the public domain (Bajaj, Hero, Honda, Mahindra, Maruti Suzuki, Tata), while the remaining four (Ashok Leyland, Eicher, Hyundai, TVS) claim to have a policy but these documents are not available in the public domain.

FINDING 2

OSH Policy for Non-Permanent Workers at Par with Permanent Workers

The occupational safety and health policies of most OEMs do not explicitly state that they cover contract/ casual/ temporary workers and other categories such as trainees/apprentices/ probationers even in their own factories. Two OEMs have a charter of workplace guidelines for contract workers which includes health and safety (Bajaj) or a code of conduct that covers OSH and is applicable to contract workers (Hero).

Five OEMs have mentioned compulsory safety induction/trainings of contract workers in their reports (Eicher, Mahindra, TATA, Ashok Leyland, TVS) while four OEMs have told Safe in India that their OSH policies cover them (Honda, Hyundai, Maruti Suzuki, TATA).

FINDING 3

Supplier Code of Conduct

Four OEMs (Eicher, Mahindra, Tata, Honda-parent company) now have Supplier Code of Conduct (SCoC). Mahindra mentions that its SCoC is applicable to all suppliers, and it includes OSH compliance. Suppliers at each tier are expected to exercise due diligence in regard to social and environmental responsibility. Honda mentions that its SCoC is applicable to all suppliers “to disseminate these guidelines to sub tiers throughout the supply chain”. Eicher has an SCoC which includes OSH and expects “the Supplier shall implement a sustainable procurement policy for its own suppliers, aligned to EML’s Supplier Code of Conduct”.

FINDING 4

Human Rights Policy in public domain

Four OEMs now have a stated human rights policy in the public domain (Bajaj, Eicher, Mahindra, Hondaparent company). Hyundai Motor’s parent company has a human rights policy, which also mentions OSH, working hours, and grievance redressal. The company told SII verbally last year that the policy is applicable to the Indian subsidiary too. Ashok Leyland, Hero and TVS have covered human rights only partially (child labour and/or forced labour etc.) as Indian legislation covers these. Maruti Suzuki, Tata and TVS have confirmed in their documents that their human rights policy has been formulated, but is not available in the public domain.

FINDING 5

Standard Operation Procedures (SOP) for deeper supply chain

None of the OEMs appears to have an SOP or an implementation plan for their supply chains, which is the same position as last year.

…However, there are some good practices

Mahindra reports that it implements its Human Rights Policy through contractual agreement. Maruti, Honda, and Hero are members of the ISH-Maruti-Honda-Hero-SII joint platform at Gurugram to prevent accidents in the auto-sector supply chain. Thirty audits of suppliers have been conducted by the three OEMs and a report on best practices across the deeper supply chain is awaited.

The Tata CoC states that “We shall comply with the laws of the countries in which we operate and any other laws which apply to us. With regard to those provisions of the Code that are explicitly dealt with under an applicable law or employment terms, the law and those terms shall take precedence. In the event that the standards prescribed under any applicable law are lower than that of the Code, we shall conduct ourselves as per the provisions of the Code.”.

The Honda supplier sustainability guidelines state “We expect our suppliers to uphold these guidelines and cascade them down to their supply chain”. And as per the auto maker’s general purchase agreement (GPA), a penalty is imposed on suppliers if they do not adhere to the supplier sustainability guidelines.

Maruti and its suppliers have established the MACE (Maruti Centre for Excellence) which will conduct trainings on OSH in the near future, including lessons on operating press machines safety.

Policy Recommendations

- Include all contract workers in own factories in the OSH policy framework

- Create, publish, and implement a Supplier Code of Conduct (SCoC)

- Create, publish, and implement a standard operating procedure (SOP) for supply chain factories

- Report annually on Indicator 8.8 of SDG 8 (the only SDG indicator about worker safety)

- Demand minimum compliance from the supply chains (e.g., all workers should be covered by ESIC from their first workday)

Operational Recommendations for OEM boards

- Take responsibility for worker safety in the deeper supply chain

- Create a joint industry-level task force with Society of Indian Automobile Manufacturers (with some participation from SII)

- Map the deeper supply chain

- Improve transparency and accountability of accident reporting in the supply chain, weed out habitual offenders and reward safest factories, commercially

- Initiate ground-level actions, e.g., honest worker safety audits and worker training

For the Society of Indian Automobile Manufacturers (SIAM)

- Bring the auto industry together to create a joint task force for OEMs and other stakeholders to prevent accidents in the auto-sector deeper supply chain, while also improving productivity.

- Set up a permanent joint safety team/working group of SIAM and Automotive Component Manufacturers Association of India (ACMA), with SII’s participation as required, to showcase good practices and train members on strategic and tactical costs of accidents and how to reduce them.

- Establish industry standards for safety in auto sector manufacturing.

- Integrate worker safety and health as core organisational values of its members.

- Support SIAM and ACMA members in complying with National Guidelines on Responsible Business Conduct (NGRBC) for long-term business success and compliance.

For the Central and State Labour Ministry

- Central and State Labour Ministries should drive calibrated actions to achieve the objectives of the Occupational Safety and Health Policy, 2009.

- Use data from ESIC to determine selection of factories for inspection and conduct safety surveys and studies.

- Create a reliable accident/injury reporting and governance system, and use it for constant continuing improvements, including strengthening of ISH in the states to improve factory inspections (irrespective of their new role as ‘facilitators’) and penalties for repeat offenders.

- Set up a confidential helpline for workers to report unsafe conditions and accidents in factories.

- Introduce a practical policy and mechanism for safety training of contract and migrant workers.

The Crux of the Matter…

SafetyNiti 2021 reported that, in India, most industrial accidents occur while operating machinery, according to 2014-2017 data from IndustriALL, a global union of workers. A news article reported the Labour Ministry’s response in Parliament in 2021, on data pertaining to factory deaths between 2014 and 2018 (the latest that the Ministry had) – factory deaths rose by 20 percent between 2017 and 2018 according to the ministry.

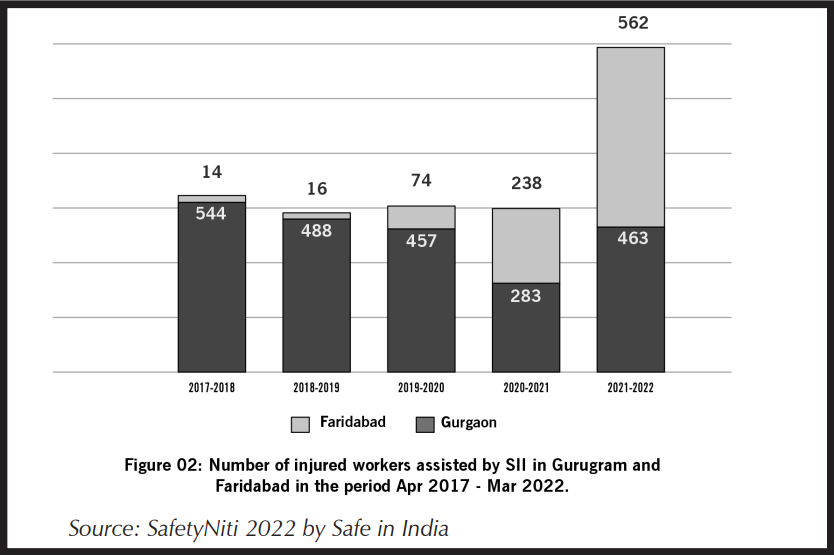

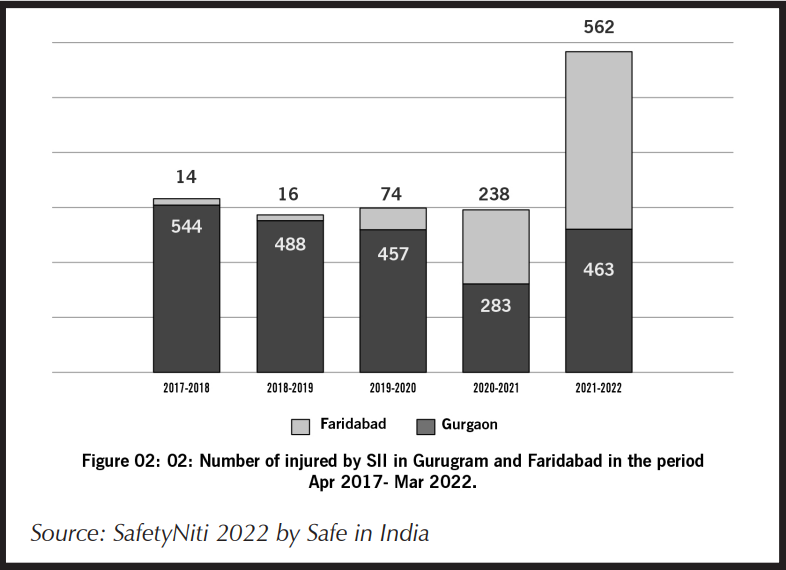

A relatively small outreach team at SII, which operates mainly in Gurugram, Manesar, and more recently also in Faridabad, has met and assisted 3955 such injured workers during 2016-2022. Of which, 80 percent are from the auto sector supply chain and 63.6 percent of them have lost hands and/or fingers, disabling them permanently. Just in FY21-22 SII assisted 1000+ workers of whom 80 percent were again from the automobile industry. This increase is mainly due to SII expanding its operations in Faridabad, which appears to have even poorer working conditions than Gurugram.

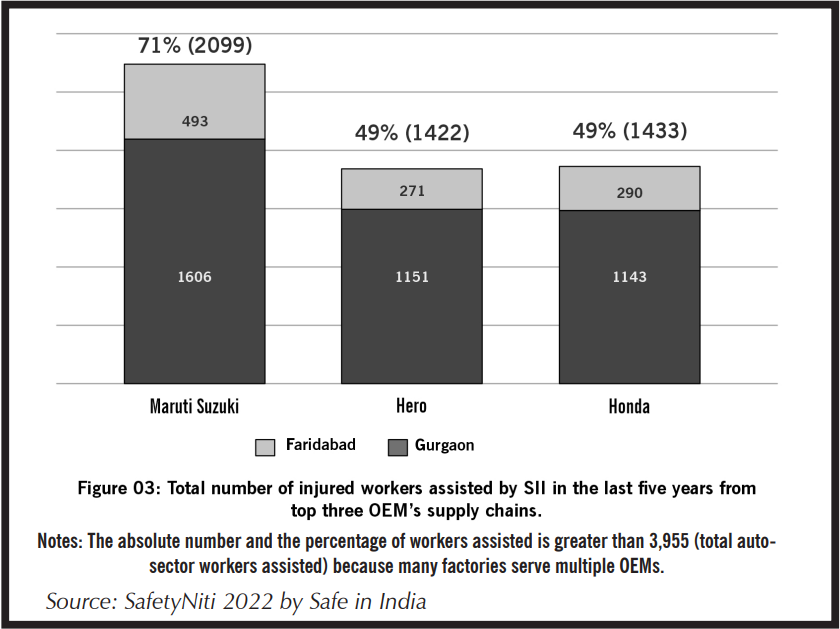

Most injured auto-sector workers in the Gurugram-Manesar-Faridabad industrial belt continue to be from factories supplying to three largest OEMs in Haryana. Approximately 80 percent of workers in the automobile sector assisted by SII in FY21-22 reported that they were injured in factories supplying to one or more of the three largest OEMs in the Gurugram-ManesarFaridabad belt: Maruti Suzuki, Hero and Honda. Although this has reduced from 90 percent in the past year, the impact of Covid-19 on this trend is unclear. These three, therefore, remain the largest OEMs with the most potential to improve this situation.

Migrant workers continue to be the most vulnerable and largest in proportion in the automobile sector

In FY 21-22, 87 percent of the injured workers assisted by SII were interstate migrants from across India; 80 percent of these had migrated from Uttar Pradesh and Bihar. This proportion dropped from 92 percent in the previous five years reported in CRUSHED 2021, probably on account of reverse migration

during Covid lockdowns. As stated in past reports, the quality of lives and work of Indian migrants is intertwined to a significant extent with the quality of work offered by India’s auto sector – the largest GDP contributor to overall manufacturing sector. Without improving working conditions for these migrant workers – there are around 450 million of them in the country – and indeed non-migrants, we cannot achieve a decent work environment for workers or expect a thriving country that is equitable for all its citizens.

Contractual employment remains a dominant pattern of employment for auto-sector workers in Haryana (Gurugram and Faridabad) and indeed nationally

In FY 21-22, 56 percent of the total workers assisted by SII were in contractual employment. This is a reduction from the previous years, especially in Faridabad, which appears to have a lower proportion of injured contract workers (47 percent, down from 64 percent) in the year than Gurugram (68 percent, down from 75 percent). This drop may be a result of Covid reverse-migration when contract workers may have left in larger numbers than permanent workers. Alternatively, the working conditions for permanent workers may have deteriorated further given that the total injured workers assisted were back to pre-Covid levels. This will be explored further in CRUSHED 2022. The above is broadly in line with ACMA reports that state that in the components industry, nearly 70 percent of the workforce comprises contract workers. SafetyNiti 2022 therefore specifically seeks treatment of contract workers at par with permanent workers in OEM policies for their own factories and those of their suppliers.

To be sure, Safe in India is not a trade union. Neither is it affiliated to any political party or labour organisation. The organisation came together to create a positive impact for the safety of Indian auto workers. The organisation doesn’t charge workers for assistance rendered, but instead raises funds from the alumni networks of its founders and well-wishers. SII is “solution centric” and seeks systemic long term solutions to the problems faced by automobile workers.

NEXT »